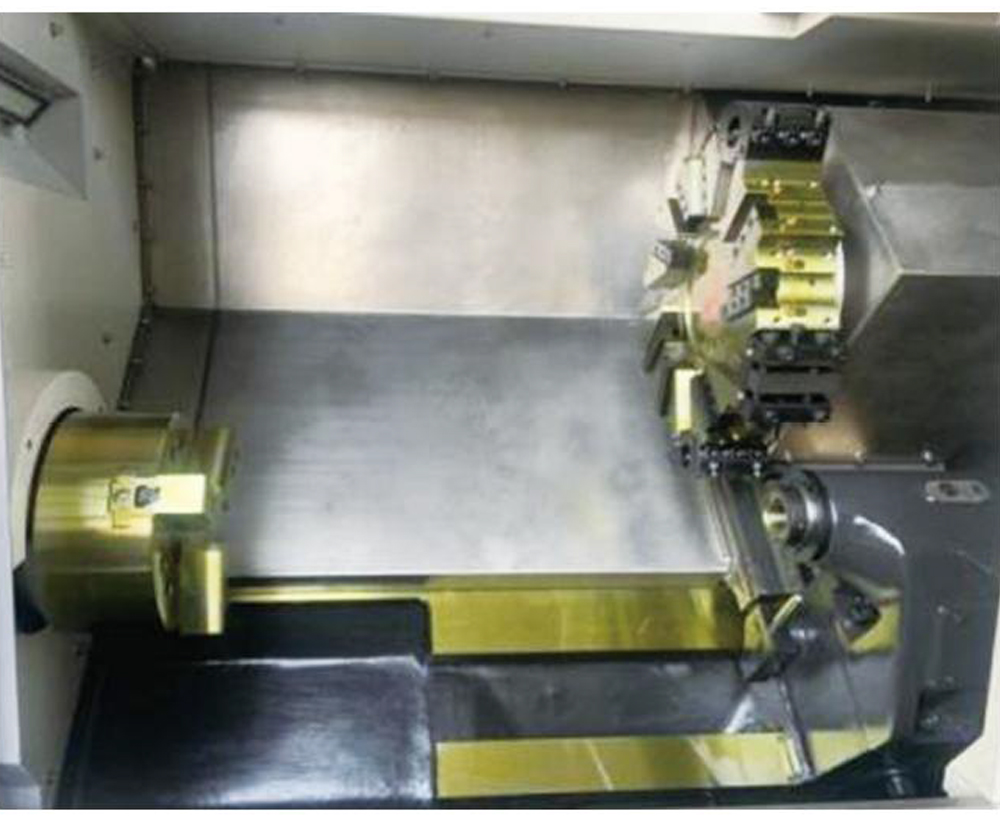

MJ520

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video: https://www.youtube.com/@Chinamachinetool

Key Features:

|

Projects |

Content |

Unit |

MJ-18 |

MJ-460 |

MJ-520 |

|

Capacity |

Maximum workpiece rotation diameter on the bed |

mm |

Ø360 |

Ø460 |

Ø600 |

|

Maximum workpiece turning diameter (over the slide) |

mm |

Ø220 |

Ø330 |

Ø430 |

|

|

Maximum turning diameter of disc workpiece |

mm |

Ø180 |

Ø350 |

Ø390 |

|

|

Maximum workpiece turning length |

mm |

310 |

622/1122 |

590/1030/1500/2000 |

|

|

Spindle |

Spindle speed range |

r/min |

45-4500 |

35-3500 |

35-3500 |

|

Maximum spindle output torque |

N.m |

63.5N.m |

163N.m |

235N.m |

|

|

Spindle head/spindle through-hole diameter |

mm |

A2-5/ Ø 52 |

A2-6/ Ø56 |

A2-8/ Ø 80 |

|

|

Spindle bore taper |

|

1:20 |

1:20 |

1:20 |

|

|

Maximum diameter of pulling tube through hole |

mm |

Ø40 |

Ø43 |

Ø65 |

|

|

Hydraulic chucks |

inch |

6″ |

8″ |

10″CSC |

|

|

Travel |

X-axis maximum travel |

mm |

110 |

215 |

185 |

|

Z-axis Maximum travel |

mm |

310 |

675/1165 |

490/990/1490/1990 |

|

|

X/Z axis rapid traverse speed |

m/min |

18/24 |

18/24 |

12/16 |

|

|

Motor |

Spindle motor |

kW |

5.5/7.5 |

11/15 |

15/18.5 |

|

Turret |

Tool holder form |

|

Horizontal hydraulic tool holder |

Horizontal hydraulic tool holder |

Horizontal hydraulic tool holder |

|

Number of tool holder positions |

position |

8 stations |

8/12 stations |

12 stations |

|

|

Turning tool / Boring bar specifications |

mm |

20×20/Ø32 |

20×20/Ø32 |

25×25/Ø40 |

|

|

Tool change time (single step) |

S |

≦0.6 |

≦0.6 |

≦0.6 |

|

|

Tail stock |

Tailstock sleeve diameter |

mm |

Ø60 |

Ø85 |

Ø85 |

|

Tailstock sleeve retraction method/stroke |

mm |

Hydraulic (programmable)/90 |

Hydraulic (programmable)/90 |

Hydraulic (programmable)/90 |

|

|

Sleeve bore taper |

MT |

MT5# |

MT5# |

MT5# |

|

|

Tailstock movement method/locking method |

|

Turret dragging/ manual locking |

|||

|

Tailstock body travel |

mm |

245 |

545/1127 |

490 |

|

|

Accuracy |

Repeat positioning accuracy |

mm |

X/Z:0.005/0.005 |

X/Z:0.005/0.007 |

X/Z:0.005/0.005 |

|

Positioning accuracy |

mm |

X/Z:0.012/0.012 |

X/Z:0.01/0.013 |

X/Z:0.013/0.02 |

|

|

Roundness of machined workpiece |

mm |

0.003 |

0.003 |

0.003 |

|

|

Dimensional accuracy of machined workpiece |

mm |

IT6 level |

IT6 level |

IT6 level |

|

|

Adding surface roughness (non-ferrous metal) |

|

Ra0.4 |

Ra0.4 |

Ra0.8 |

|

|

Others |

Dimension (L*W*H) |

cm |

192×158×176 |

307/367×156× 194 |

297/369/419/490×156×194 |

|

Net weight |

kg |

3000 |

4000/4200 |

4900 |

|

|

Total electrical capacity |

kVA |

15 |

30 |

30 |

|

|

NC System |

|

Fanuc 0i-TF Plus |

Fanuc 0i-TF Plus |

Fanuc 0i-TF Plus |

|