Micro CNC 100 SP/HP

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video: https://www.youtube.com/@Chinamachinetool

Key Features:

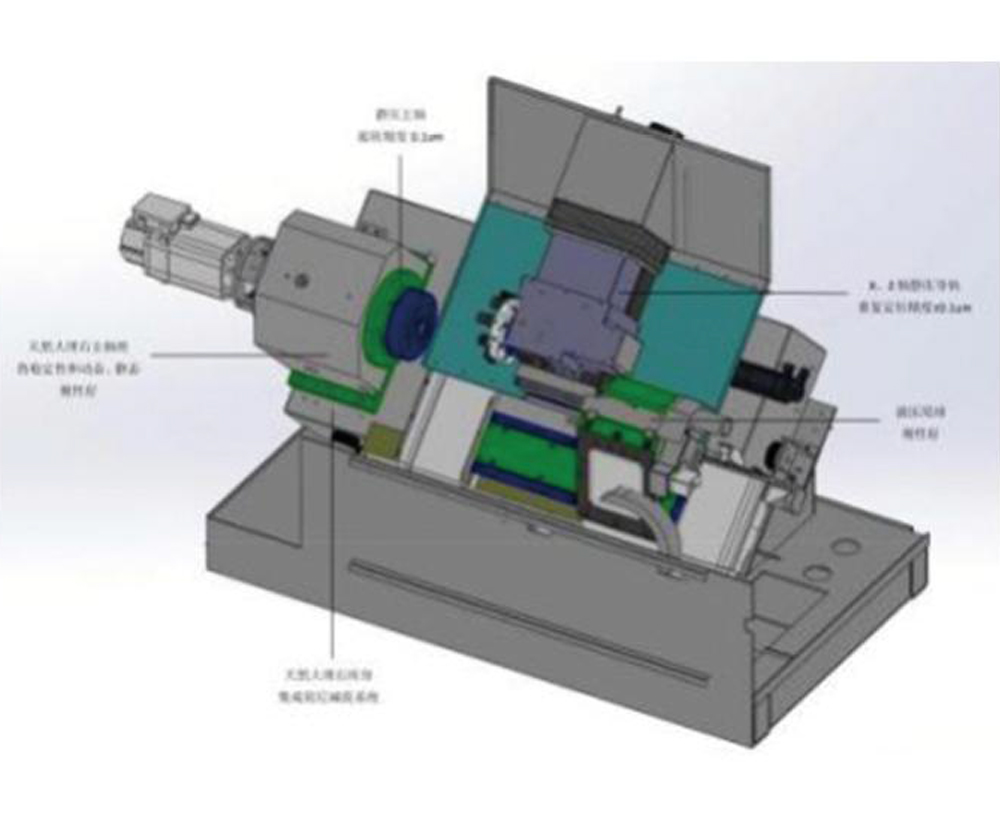

The Mirco is able to achieve micron accuracies in hardened steel due to superb static and dynamic stiffness and the thermal stability of the machine. The construction is unique due to the application of a fully hydrostatic and wear free main spindle and slides together with The use of a very stable natural granite machine base.

Ultra precision. It all starts at the base.

All Mirco machines have a natural granite machine base with an integrated vibration damping system. Natural granite is the perfect machine base. It is completely stress free , has very good damping properties, is corrosion free and has a low thermal expansion coefficient ent improving thermal stiffness .

Natural granite the perfect base for an ultra precision machine. Natural granite base:

Good damping properties

High thermal stability; High static and dynamic stiffness; Free of stress; Corrosion free

Hydrostatic slides and main spindle.

The main spindle bearings and slide guideways are the most important machine elements in a lathe, determining part accuracies of the workpieces and the lifetime of the machine.

The hydrostatic system in the Mirco Machine series is far superior to any other conventional system and offers many advantages.

Excellent runni

Rigid natural granite machine base with an integrated system of vibration dampers

Headstock housing of natural granite for improved static and dynamic stiffness and thermal stability

Hydrostatic, high speed linear driven X- and Z-slide with a ± 0.1 µm repeatability

Sealed type direct linear slide measuring system;Hydrostatic main spindle with a 0.15 µm run-out.

Heat and vibration generating elements are fully isolated from the machine

External hydraulic service unit.;Fanuc 0i control with a 0.1 micron resolution

|

Model |

Micro CNC 100 SP/HP |

Micro CNC 100XLD SP/HP |

Micro CNC 100XLS SP/HP |

Micro CNC 500XL SP/HP |

|

Max.Turning Diameter |

φ380 mm*2 |

φ610 mm |

φ350 mm |

φ500 mm |

|

Max. Distance between Centers |

φ200x350 mm |

N/A |

φ200 x1000 mm |

N/A |

|

Max. weight between Centers |

50 kg*3 |

200kg |

50 kg*3 |

300 kg |

|

Max. Spindle Speed |

4000 rpm*4 |

2000 rpm |

4000 rpm*4 |

2000 rpm*4 |

|

Hydrostatic Spindle Run-out |

0.15μm/0.2μm |

0.2μm/0.25μm |

0.15μm/0.2μm |

0.15μm/0.2μm |

|

X/Z Axis Position accuracy |

1μm/2μm |

1μm/2μm |

2μm/3μm |

1μm/2μm |

|

X/Z Axis Repeat Position Accuracy |

0.2μm/1.5μm |

0.2μm/1.5μm |

0.2μm/1.5μm |

0.2μm/1.5μm |

|

control resolution |

0.01μm/0.1μm |

0.01μm/0.1μm |

0.01μm/0.1μm |

0.01μm/0.1μm |

|

X Axis Travel |

240mm |

340mm |

200mm |

400mm |

|

Z Axis travel |

350mm*5 |

350mm |

890mm |

750mm |

|

X/Z Axis Quick Move Speed |

10m/min |

12m/min |

12m/min |

12m/min |