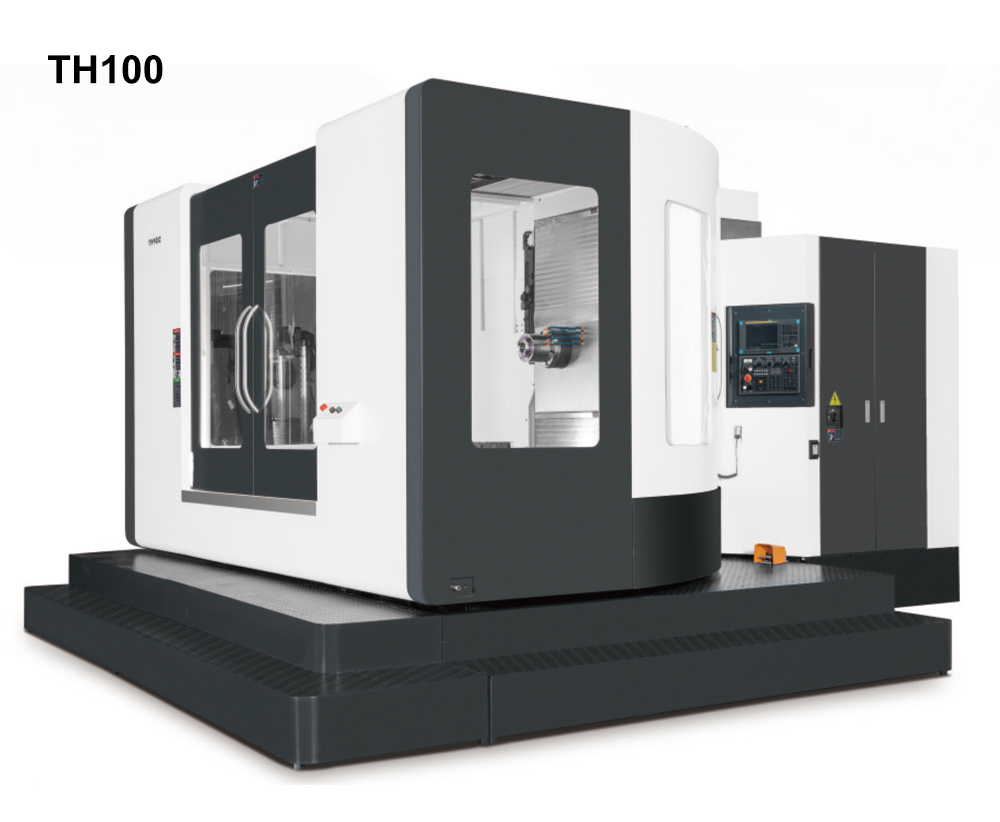

TH100

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video: https://www.youtube.com/@Chinamachinetool

Key Features:

TH-100 horizontal machining center is made of high-grade Meehanite cast iron and box-shaped structure design. After proper annealing treatment to eliminate internal stress, the material is tough and the box-shaped structure design makes the machine have sufficient rigidity and strength. , the whole machine shows the characteristics of heavy cutting capability and high reproduction accuracy, without generating overturning torque throughout the process.

Features:

+ The guide rails and screw rods of the whole machine adopt a pressurized centralized timing and quantitative lubrication system, and advanced pressurized metering parts are used in the oil circuit to control the oil volume; the oil supply cycle and oil supply volume of each lubrication point can be controlled Adjust and realize fully automatic centralized lubrication through electrical system control.

+ Casting processing adopts high-precision pentahedral gantry processing, which can complete milling, drilling, tapping, etc. on five sides with only one clamping; reducing clamping errors and improving processing accuracy.

+The machine tool adopts Taiwan's high-precision spindle assembly, with a speed of up to 6000rpm; it is also equipped with a spindle air curtain device to ensure stable spindle accuracy and increase service life. The rotary table can be equipped with 1°×360° or 0.001°.

+The whole machine adopts imported heavy-duty high-precision roller guide rails, which can withstand heavy-load cutting and has good stability; the Z-axis is used as the cutting axis. In order to ensure the stability of processing, it is equipped with 65 roller heavy-duty guide rails to meet different processing tasks. situation needs.

The +X/Z axis adopts a φ63 ground C3 grade high-precision high-thrust screw rod, equipped with a set of imported angular contact bearings, supported and pre-stretched on both sides to ensure transmission accuracy.