THMC6380

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video: https://www.youtube.com/@Chinamachinetool

Key Features:

|

Description |

unit |

THMC6350 |

THMC6363 |

THMC6380 |

THMC63100 |

|

Pallet |

|||||

|

Pallet L/W |

mm |

500×500 |

630×630 |

800×800 |

1000×1000 |

|

Pallet model |

|

Threaded hole |

Threaded hole |

Threaded hole |

Threaded hole |

|

End-tooth index |

° |

1°×360 (End tooth palte) |

|||

|

Optical scale index |

|

Option: 0.001°×360000 (Continuous) |

|||

|

Max. rotary speed to Rotary table |

r/min |

15 |

12 |

10 |

5 |

|

Max pallet load |

Kg |

800 |

1200 |

2000 |

2500 |

|

Max. workpiece Dia. |

mm |

Ф750 |

Ф950 |

Ф1250 |

Ф1650 |

|

Pallet number |

pcs |

2 |

2 |

2 |

2 |

|

Pallet exchange time |

s |

16 |

16 |

18 |

20 |

|

Travel |

|||||

|

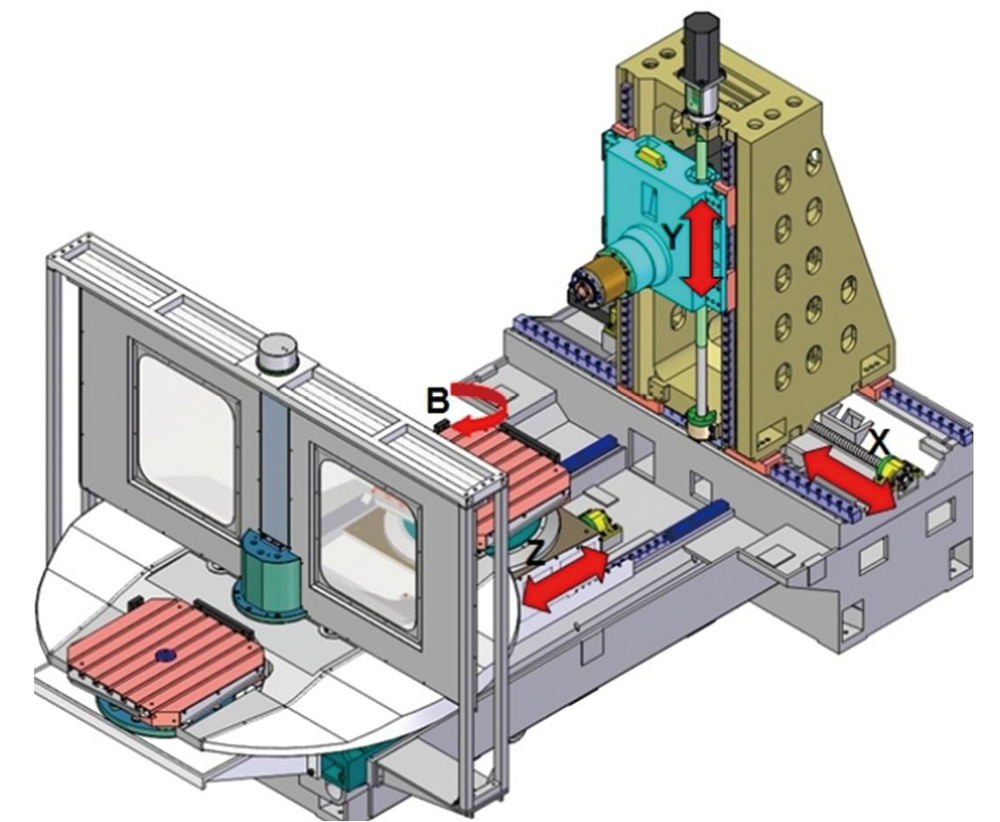

X (Column) |

mm |

700 |

1000 |

1300 |

1600 |

|

Y (Headstock) |

mm |

600 |

800 |

1000 |

1200 |

|

Z (Worktable) |

mm |

600 |

900 |

1100 |

1300 |

|

Spindle center to pallet surface |

mm |

50~750 |

25~925 |

50~1050 |

100~1300 |

|

Spindle nose to pallet center |

mm |

150~1050 |

150~1050 |

200~1300 |

200~1500 |

|

Spindle |

|||||

|

Spindle taper |

|

50 |

50 |

50 |

50 |

|

Spindle rpm |

r/min |

20~6000 |

20~5000 (Optional:8000) |

||

|

Speed selection |

|

Programmable in full range |

|||

|

Spindle motor |

Kw |

18.5/22 |

18.5/22 |

30/37 |

30/37 |

|

Max. torque |

N.m |

500 |

500 |

307 or 1288( add reducer) |

|

|

Tool magazine |

|||||

|

Number of tool |

|

Standard:40 (Optional:60;80;120) |

Standard:40 (Optional:60;80;120;160) |

||

|

Tool type |

|

BT 50 (Optional:ISO50;SK50) |

BT 50 (Optional:ISO50;SK50;JT50) |

||

|

draw bar type |

|

ISO7388/2-A |

ISO7388/2-A |

ISO7388/2-A |

ISO7388/2-A |

|

Max tool diameter |

mm |

Φ125(full loaded) |

Φ125(full loaded ) |

Φ125(full loaded ) |

Φ125(full loaded |

|

Φ250(interval loaded) |

Φ250(interval loaded) |

Φ250(interval loaded) |

Φ250(interval loaded) |

||

|

Max tool length |

mm |

400 |

450 |

500 |

600 |

|

Max tool weight |

Kg |

20 |

20 |

25 |

25 |

|

T-T tool change time |

s |

3.5 |

3.5 |

4.5 |

4.5 |

|

Tool selection |

|

Stochastic; bi- directional |

Fixed tool section; bi- directional |

||

|

Axis driven |

|||||

|

Federate |

m/min |

0~20 |

0~20 |

0~20 |

0~20 |

|

Rapid feed |

m/min |

45 |

45 |

40 |

40 |

|

Location feedback(X、Y、Z、) |

|

Encoder |

Encoder |

Encoder |

Encoder |

|

Rotary (B-axis servo motor) |

kw |

3 |

4 |

4 |

4 |

|

Min. Increment(X/Y/Z) |

|

0.001 (Optional: 0.0001) |

|||

|

Min. Increment(A/B) |

|

0.001 (Optional: 0.0001) |

|||

|

Accuracy |

|||||

|

Linear axis positioning accuracy |

mm |

Standard: 0.015 Optional:0.008 |

|||

|

Linear axis repeatability |

mm |

Standard: 0.008 Optional:0.004 |

|||

|

Rotary table positioning accuracy |

″ |

Standard: 8 Optional:6 |

|||

|

Rotary table repeatability |

″ |

Standard: 4 Optional:3 |

|||

|

Machine Standard GB/T 18400.1; Optional: GB/T 20957.1-2007 |

|||||

|

Installation data |

|||||

|

Machine weight |

t |

17 |

18 |

24 |

32 |

|

Total capacity |

KVA |

60 |

60 |

100 |

100 |

|

Power requirement |

|

380V/50Hz/3 phase |

|||

|

Compressed air input pressure |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

|

Compressed air flowrate |

L/min |

380 |

380 |

380 |

380 |

|

Electric System |

|||||

|

FANUC 0i MF Plus(Type5) |

|||||