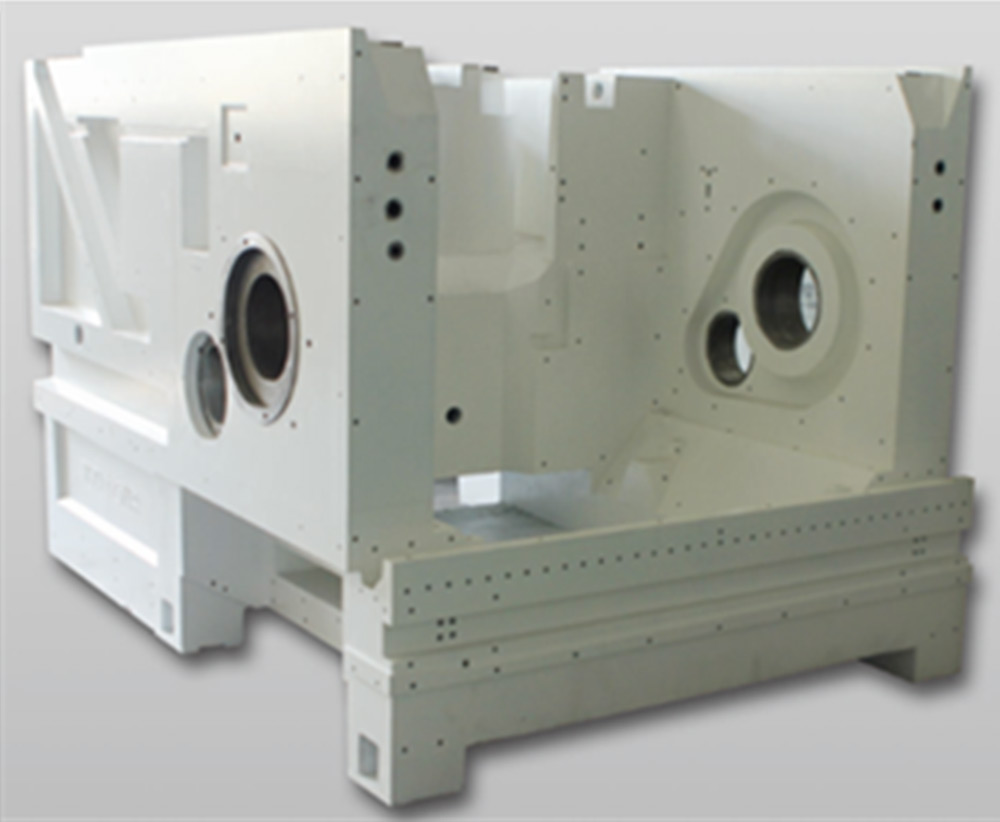

KMC400-U (5 axis)

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video: https://www.youtube.com/@Chinamachinetool

Key Features:

Based on a compact Gantry-type design, this series offers all benefits of a high-capacity 5-axis machining center The machine frame is made of high-end mineral-casting featuring all known benefits of this premium material, including virtually perfect vibration dampening and high thermal stability High-quality linear guides and preloaded ball screws on X, Y, and Z axis for maximum precision, low maintenance and wear-resistance Y-travel driven with two synchronised servomotors Fast feeds and rapid feeds up to 48 m/min (optionally up to 60 m/min), and axis acceleration up to 1 g for maximum metal removal rates Tool changer is integrated in the machine column NC rotatary table is solidly supported at 2 points inside the gantry and swivels up to 260° on A axis and 360° on C axis Wide jaw opening with large work space accommodates large workpieces during swiveling Solid construction and bilateral torsion-free drive accommodate high workpiece weights Turning and swiveling axis are close at the workpiece

| Model | KMC 400U | KMC 800U |

| Working area | ||

| A axis swivel range | -130° bis +130° | -130°bis +130° |

| C axis swivel range | 360° | 360° |

| Table dimensions | 370x370 mm | 800 mm |

| Table load capacity (max.) | 500 kg | 1.400 kg |

| Number of T-slots | 8 Pieces | 16 Pieces |

| Spindle nose-to-table surface distance | 144 - 490 mm | 140 - 680 mm |

| Throat | 350 mm | 800 mm |

| Workpiece diameter | 530 mm | 1.100 mm |

| Milling diameter X-axis | 350 mm | 800 mm |

| Milling diameter Y-axis | 350 mm | 800 mm |

| Cutting height Z axis | 350 mm | 500 mm |

| Travels | ||

| Travel X-axis | 350 mm | 800 mm |

| Travel Y-axis | 350 mm | 800 mm |

| Travel Z-axis | 346 mm | 550 mm |

| Headstock | ||

| Spindle speed | 18.000 rpm | 12.000 rpm |

| Spindle mount | HSK-A50 | HSK-A50 |

| A axis | ||

| Torque | 689 Nm | 5.400 Nm |

| Braking torque | 500 Nm | 7.500 Nm |

| C axis | ||

| Torque | 315 Nm | 1.240 Nm |

| Braking torque | 500 Nm | 5.000 Nm |

| Rapid feed | ||

| Rapid feed | 48.000 mm/min | 48.000 mm/min |

| Feed | ||

| Work feed | 10.000 mm/min | 10.000 mm/min |

| Tool head | ||

| Number of tool stations | 22 Pieces | 36 Pieces |

| Tool size ¢ x L (max.) | 90x230 mm | 125x300 mm |

| Tool weight max. | 5 kg | 16 kg |

| Tool-changing time chip/chip | 5 s | 8 s |

| Tool-change time tool/tool | 3 s | 4,5 s |

| Accuracies | ||

| Positioning accuracy X-axis | 5 µm | 5 µm |

| Positioning accuracy Y-axis | 5 µm | 5 µm |

| Positioning accuracy Z-axis | 5 µm | 5 µm |

| Positioning accuracy A axis | 0,004° | 0,004° |

| Positioning accuracy C axis | 0,004° | 0,004° |

| Repeatability X-axis | 3 µm | 3 µm |

| Repeatability Y-axis | 3 µm | 3 µm |

| Repeatability Z-axis | 3 µm | 3 µm |

| Repeatability A axis | 0,002° | 0,002° |

| Repeatability C axis | 0,002° | 0,002° |

| Drive capacity | ||

| Motor rating main drive | 16 kW | 30 kW |

| Motor rating coolant pump | 4 kW | 4 kW |

| Motor rating X-axis | 5,6 kW | 5,6 kW |

| Motor rating Y | 5,6 kW | 8,8 kW |

| Motor rating Z | 5,6 kW | 5,6 kW |

| Measures and weights | ||

| Overall dimensions (length x width x height) | 2.230x2.920x2.560 mm | 3.310x3.750x3.650 mm |

| Weight | 4.500 kg | 16.000 kg |