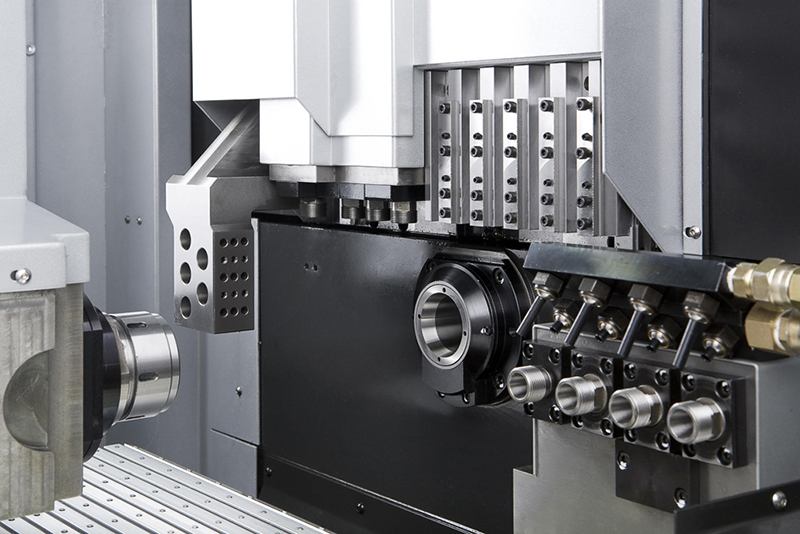

SQC385

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video: https://www.youtube.com/@Chinamachinetool

Key Features:

| Itme | SQC385 | ||

| Processing Capacity | Maximum rotating speed of spindle | Main-spindle 8000min-1/ Sub-spindle 8000min-1 | |

| Maxim turning diameter | φ38mm | ||

| Z-axis stroke | 210mm | ||

| Additional positive brake of spindle | 1/1,00° | ||

| Rapid traverse rate | 32m/min | ||

| Tool storage capacity | Outer annulus lathe tools | 6EA | |

| Non-ratary end face tools | 5EA | ||

| Cross driven tools | 4EA | ||

| Tools for sub-spindle | 4EA | ||

| Eccentricity driven tools for main-spindle | 3EA | ||

| NC | System Model | FANUC 0i-TD | |

| Number of controllable axes/Simultaneously moved axes | 7 axes/4 axes | ||

| LCD screen | 10.4″MONO | ||

| Motor Power | Main-spindle motor | 5.5/7.5KW | |

| Sub-spindle motor | 1.5/2.2KW | ||

| Cross power head motor | 0.55/1.1KW | ||

| Power head for sub-spindle motor | 1.0KW | ||

| Axis servo-motor | 1.0KW | ||

| Coolant tank motor | 0.9KW | ||

| Lubrication oil tank motor | 5W | ||

| Others | Others | 200L | |

| Lubrication oil tank capacity | 1.8L | ||

| Specifications | Center height | 1,000mm | |

| weight | 4,500kg | ||

| length | 2800mm | ||

| width | 1475mm | ||

| height | 1850mm | ||

| 二、Standard specifications of SC385 CNC system | |||

| Standard FANUC specification | Drill cycling function | ||

| All axis rigid tapping | Software panel | ||

| Hand trace function | English | ||

| Synchronous control | Cutter compensation | ||

| Reiteration control | Backlash, pitch error compensation | ||

| Parallel screw interpolation function | |||

| 三、Standard configuration of SC385 | |||

| Synchronous rotary guide bush holder unit | |||

| 4-axis cross driven tools | |||

| 4-axis back end tools | |||

| 3-axis front end tools | |||

| sub-spindle ejector | |||

| Product output device | |||

| Centralized lubricating system | |||

| Product receiver | |||

| Safety door lock | |||

| Handle Trace | |||

| Automatic sources of electricity circut breaker | |||

| chip box, standard tools and tool box | |||

| Rigid tapping on back end tools | |||

| 四、Brand and place of origin of SX385 configuration: | |||

| Product name | Brand | Place of origin | Remarks |

| Screw | THK | Japan | Precision grinding P4 level |

| Guideway | THK | Japan | Precision C3 level |

| Screw bearing | NSK | Japan | Self-adjusting centripetal, level P4 |

| Main-spindle bearing | NSK | Japan | High-speed angular contact bearing, P4 level |

| Power head bearing | NSK | Japan | Angular contact bearing, P4 level |

| Synchronous simultaneous moving axis | THK | Japan | Precision spline shaft |

| Controlling system | FANUC | Japan | FANUC 0i-TD two=channel |

| servo-motor | FANUC | Japan | &alphα eries |

| Servo, system connecting cable | Korea | original imported | |

| relay module | I/O Link | Korea | original imported |

| AC contactor | Shneider | Shanghai | joint venture |

| circut breaker | Shneider | Shanghai | joint venture |

| Strong power protection switch | LS | Korea | original imported |

| Flow detection switch | Yi Fumen | Germany | original imported |

| Electric cabinet cooling fan | Korea | original imported | |