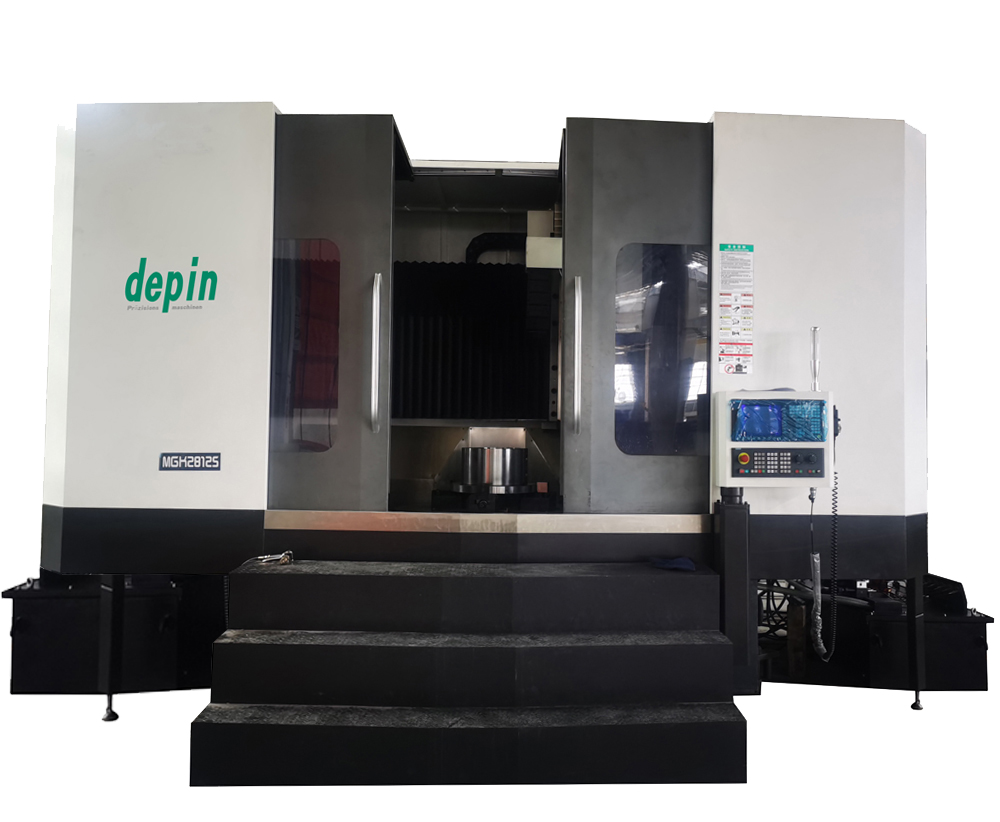

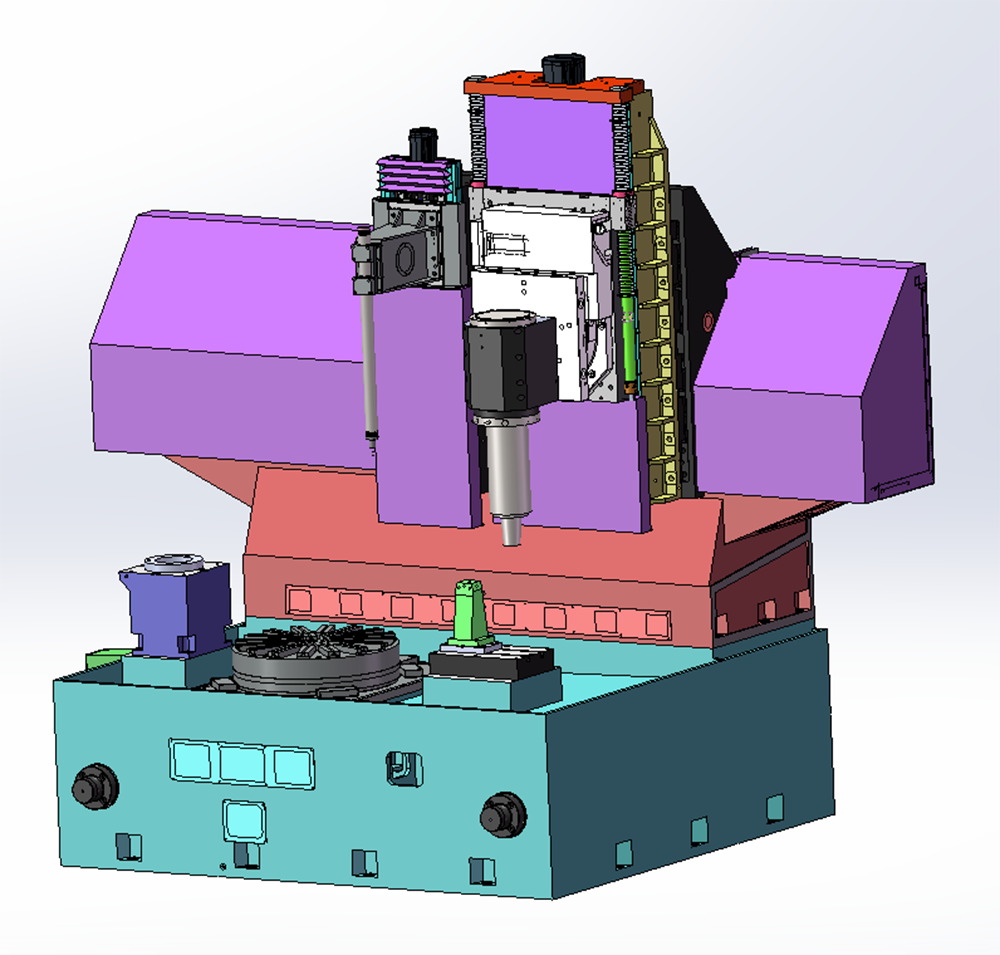

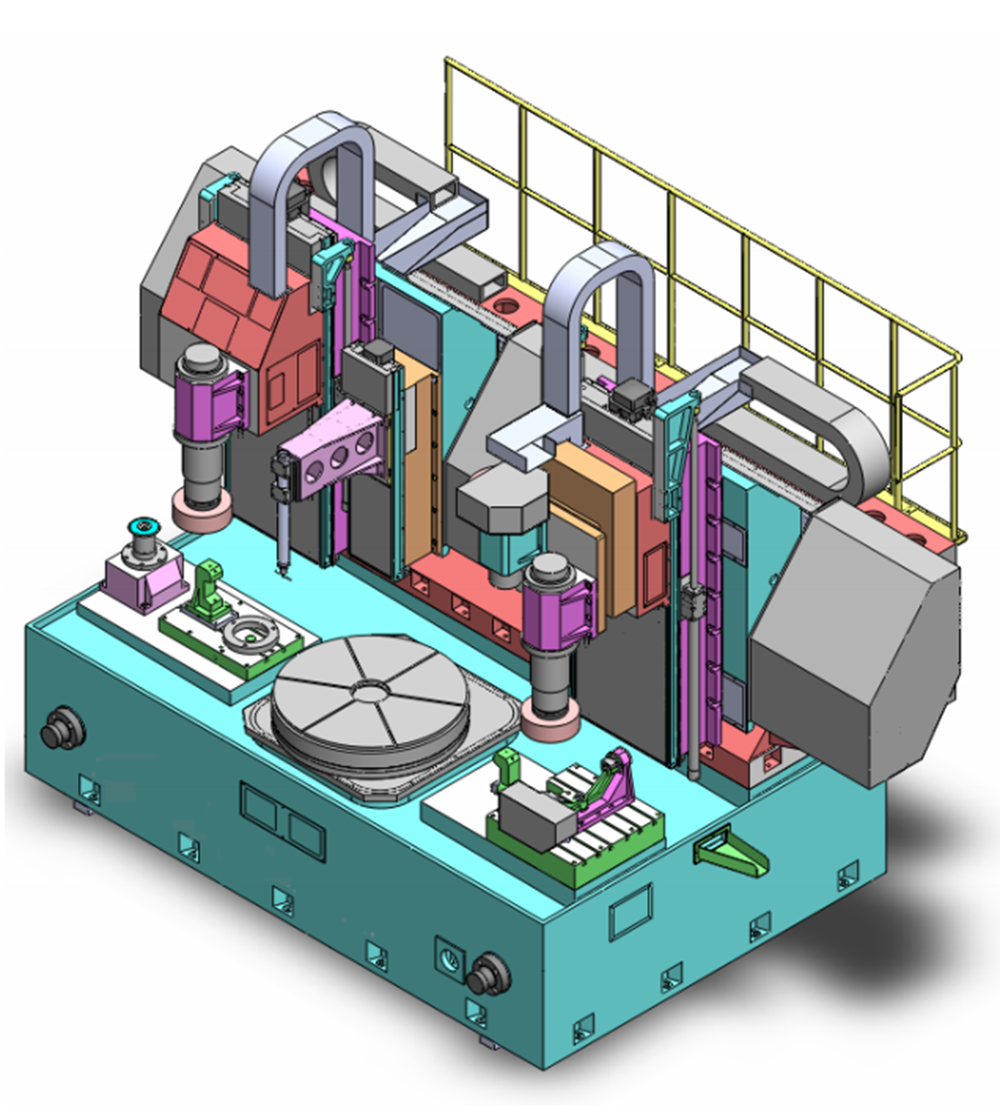

MGK28100

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video: https://www.youtube.com/@Chinamachinetool

Key Features:

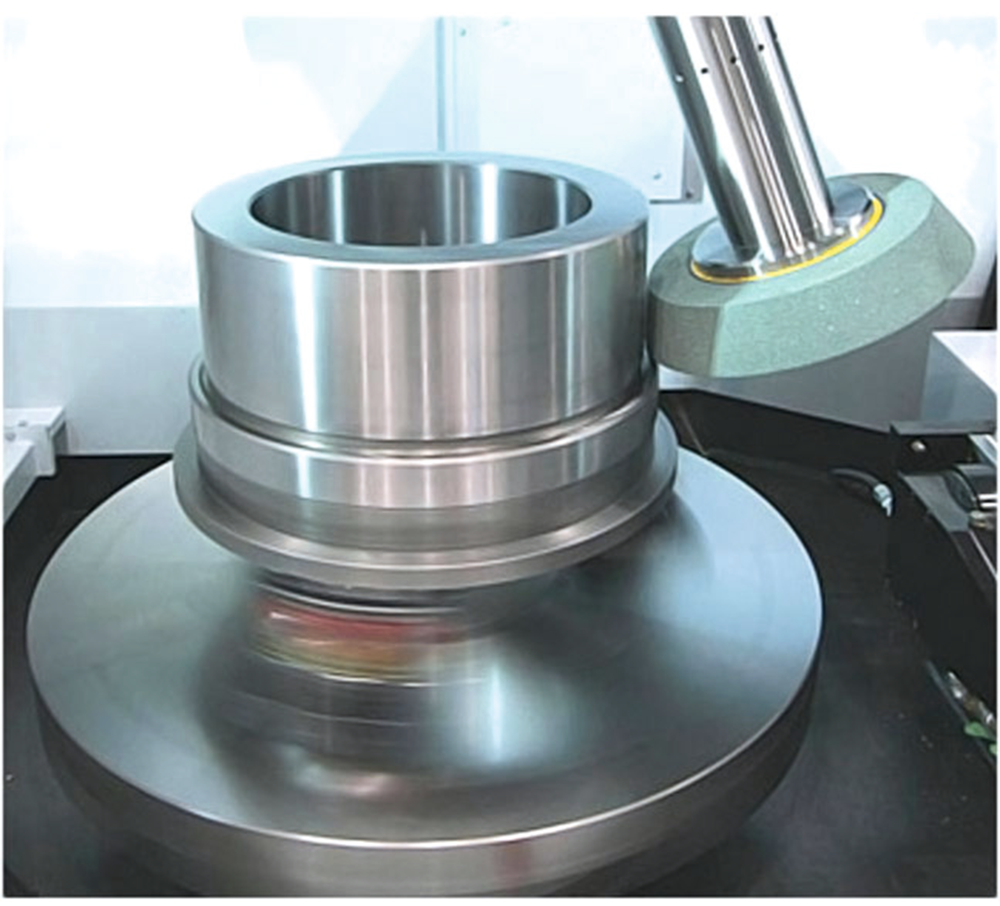

High Rigidity MGK28 series main structure adopts Japanese advanced technology,it is suitable for precision grinding of large ring,disk,sleeve and cylinder parts.

|

Model Item |

unit |

MGK2860 |

MGK2880 |

MGK28100 |

MGK28100H |

MGK28125 |

MGK28160 |

MGK28200 |

|

Capacity of processing |

||||||||

|

Maximum workpiece grinding diameter |

mm |

750 |

850 |

1100 |

1100 |

1350 |

1800 |

2200 |

|

Maximum workpiece height |

mm |

400 |

400 |

500 |

1000 |

500 |

550 |

550 |

|

Minimum grinding inner hole |

mm |

60 |

60 |

100 |

250 |

100 |

350 |

350 |

|

Maximum bearing capacity of workbench |

kg |

600 |

800 |

2000 |

2000 |

2500 |

3000 |

5000 |

|

Worktable |

||||||||

|

Diameter of working table |

mm |

600 |

800 |

1000 |

1000 |

1250 |

1600 |

2000 |

|

Speed of work table |

rpm |

200 |

200 |

60 |

60 |

60 |

50 |

40 |

|

Precision of rotating |

mm |

0.0015 |

0.0015 |

0.002 |

0.002 |

0.002 |

0.003 |

0.003 |

|

Spindle |

||||||||

|

Maximum spindle speed of vertical grinding wheel |

rpm |

10000 |

10000 |

7000 |

6000 |

7000 |

3000 |

3000 |

|

Vertical grinding wheel spindle power |

kw |

11 |

11 |

15 |

15 |

15 |

18.5 |

22 |

|

Maximum spindle speed of horizontal grinding wheel |

rpm |

- |

- |

2500 |

- |

2500 |

2000 |

2000 |

|

Horizontal grinding wheel spindle power |

kw |

|

|

11 |

|

11 |

15 |

15 |

Features

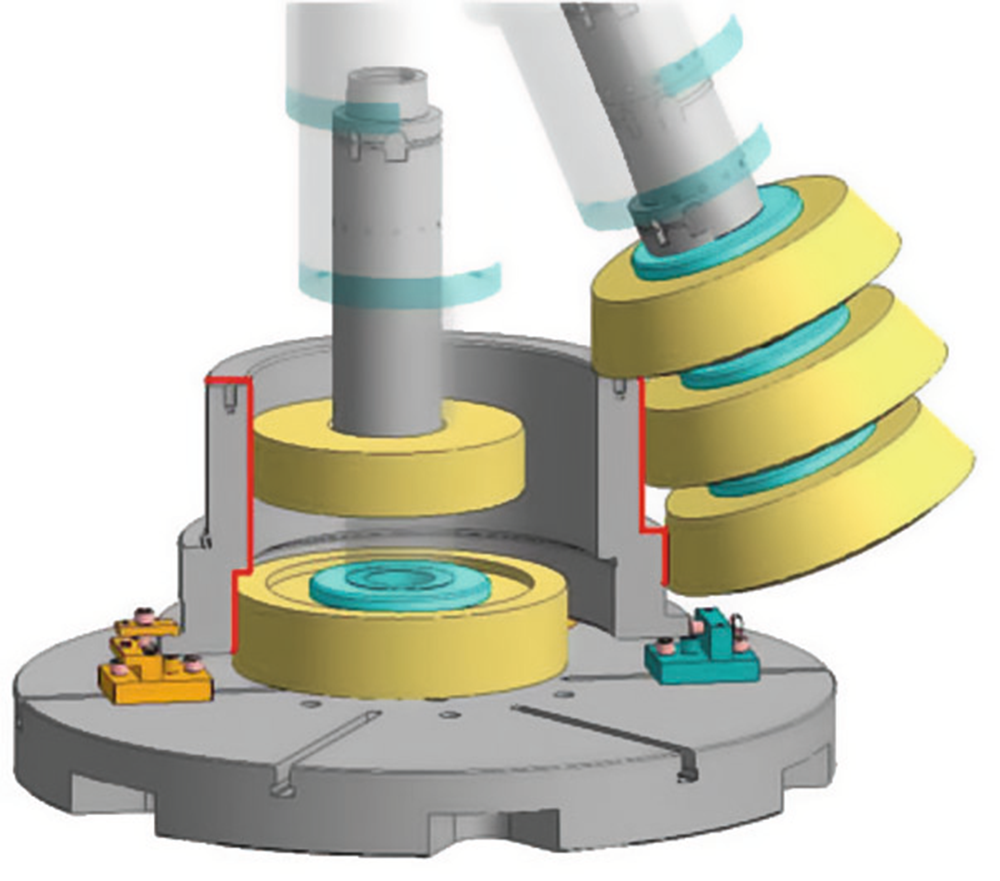

1. Adopt high precision closed static pressure rotary table and high torque permanent magnet motor direct drive, with large bearing capacity and stable operation; Table rotation accuracy (axial/radial) ≤2μm

2. High strength stair wall beam and reinforced base with full contact structure, to ensure the machine high rigidity, good precision retention;

3. The use of NSK precision bearing spindle (axial/radial ≤2μm), vertical and horizontal double spindle, to meet different processing requirements; Optional with spindle of high-precision dynamic and static spindle (axial/radial ≤1μm) to meet the needs of higher precision machining;

4. Using imported SCHNEEBERGER big size High Precision Roller Type Guideway, X axis standard with FAGOR grating ruler;

5. Rotary table oil supply system, torque motor, grinding wheel spindle, cooling system, control system are equipped with temperature control device, to ensure the stable work of key components of the whole machine;

6. The work table is equipped with standard disk, optional electropermanent magnet chuck, to meet the needs of different workpiece clamping;

7. Using fully closed cover, can be configured with high power oil mist collector, optimize the working environment.

Turbine blade grinding,Belt grinding,finish grinding,belt grinding,linishing,finishing,deburring and polishing of fan blades,leading edge inserts,gas turbine blades,compressor blades,buckets and vanes