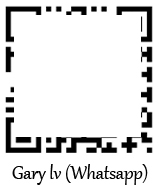

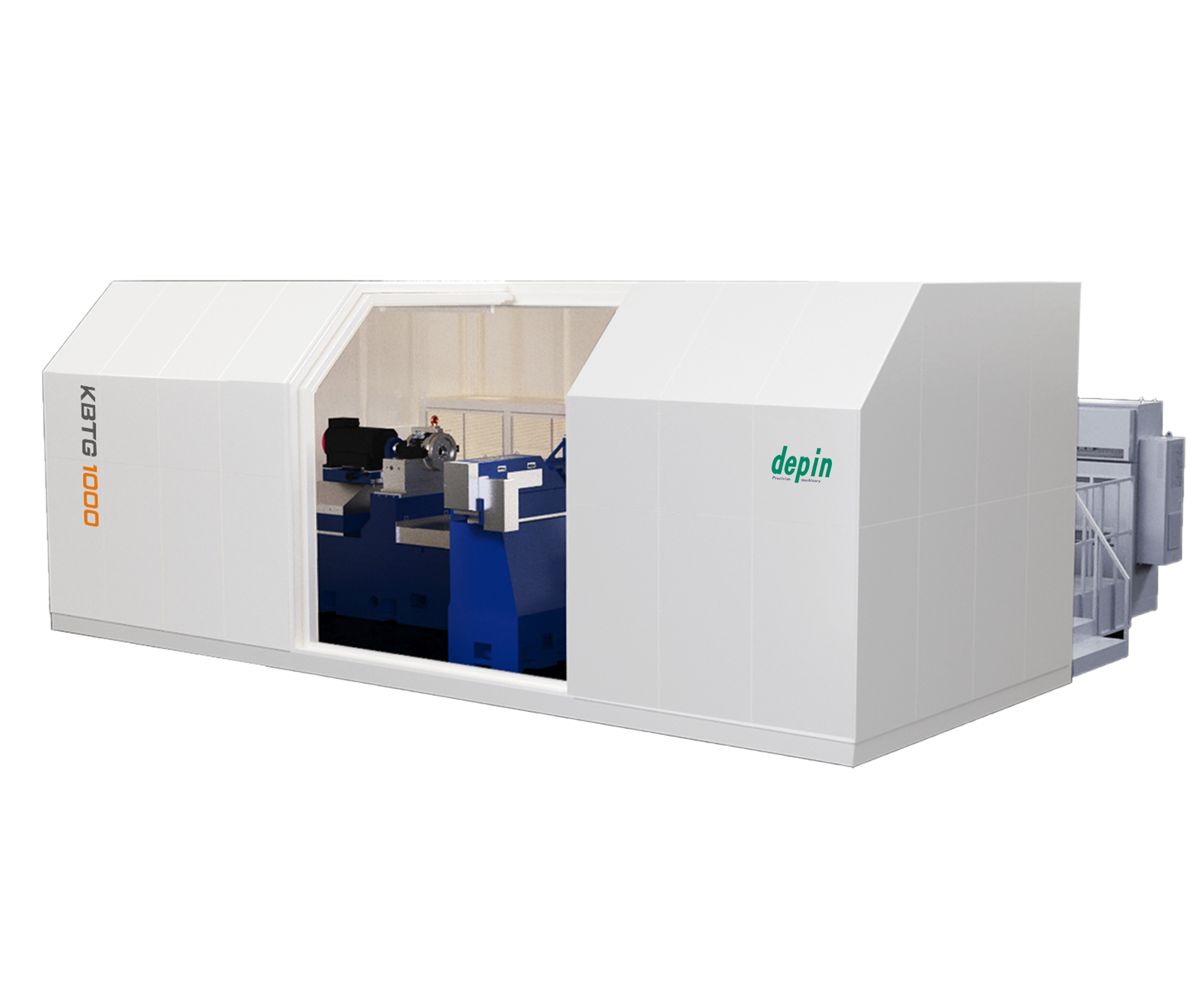

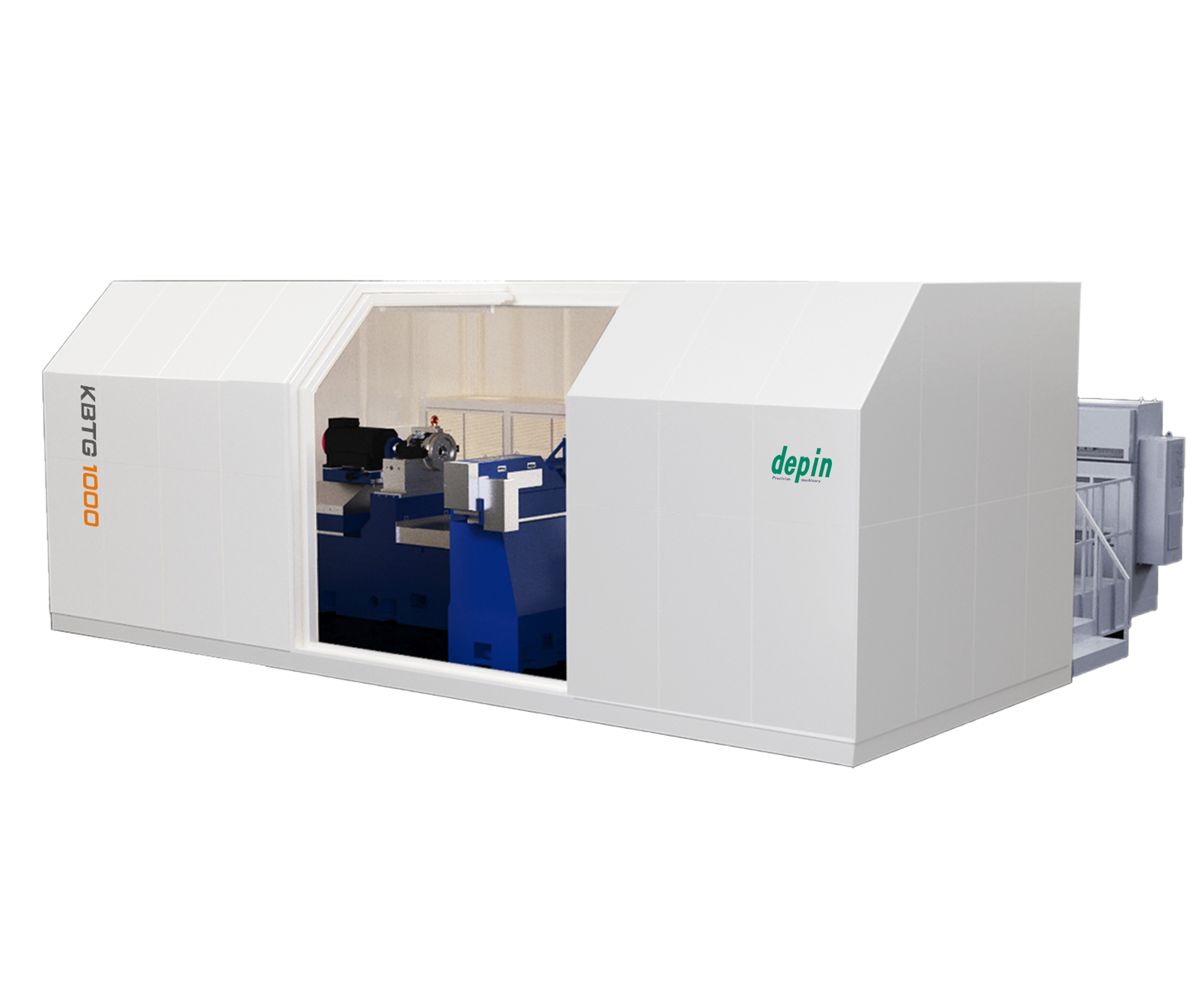

KBTG1000

Order No.:

Stock:

Delivery Time:

Without Tax: $

Machine video: https://www.youtube.com/@Chinamachinetool

Key Features:

Introduction The whole machine has a horizontal structure layout, with grinding wheel grinding and laser measurement on both sides of the workbench, so that processing and detection can be carried out simultaneously. The whole machine has a fully closed-loop high-precision control and a structural thermal balance design to ensure the high precision and precision stability of the whole machine. When the rotor rotates at high speed, the laser measurement system can realize high-speed data acquisition and analysis, and measure the radius of all rotors. The dual workpiece spindle with built-in vibration detection device can monitor and alarm the processing conditions. The double-layer protection and labyrinth seal structure of the accordion and steel cover are adopted to achieve efficient dust proof sealing. The dual grinding wheel dressing device can realize online dressing of the grinding wheel. The deburring device can realize the removal process of rotor burrs. The direct-drive grinding wheel head frame has no mechanical wear and realizes high-precision corner positioning. Equipped with a workpiece platform, workpiece hanger, in-machine air conditioner, wet dust collector, sound insulation external protection and visual monitoring system to ensure high-precision and stable processing of products. The static pressure clamp can be customized according to customer requirements.

Parameter

|

名称 |

Specification |

KBTG 1000 |

|

Processing range |

Workpiece spindle center height mm |

850

605-2000

|

|

Grinding wheel spindle |

Grinding wheel size range mm |

560~762 |

|

Workpiece spindle |

Rated power kw |

60 |

|

Grinding wheel head |

Rated torque Nm |

314.2 |

|

Travel |

Z axis movement mm |

2200 |

|

Maximum feed speed |

X/Z/W/A axis m/min |

5 |

|

Control resolution |

X/Y/Z axis mm |

0.001 |

|

Positioning accuracy |

X/Y/Z axis |

0.01 |

|

Repeat positioning accuracy |

X/Y/Z axis mm |

0.005 |

Turbine blade grinding,Belt grinding,finish grinding,belt grinding,linishing,finishing,deburring and polishing of fan blades,leading edge inserts,gas turbine blades,compressor blades,buckets and vanes